Delphi Diesel Fuel Injectors are a family of highly versatile mechanical products that can be adapted for use in a wide range of light duty, medium duty and heavy duty fuel systems for both direct injection and indirect injection diesel engines. They are precisionengineered for both mechanically- and electronically-controlled pump line nozzle systems. They can be configured in conventional bar-type designs for axial-feed or side-feed, or forged body designs for a variety of angled side-feed applications.

The nozzle valve of Delphi Diesel Fuel Injectors is mechanically closed by a high stress-capable spring, and the opening pressure is accurately set by high precision shims. Their proven, cost effective technology and application flexibility provide manufacturers with excellent value.

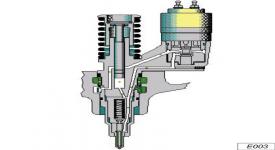

The pumping mechanism is identical to an “In line” or single-cylinder pump. The plunger, which is driven by the camshaft, moves up and down in the body. Fuel, under pressure, moves freely from engine fuel manifold, through the injector, and back into the manifold. At a certain point during the down-stroke, current is applied to the actuator. This current generates a magnetic field within the actuator and causes a high pressure valve to close.

The pumping mechanism is identical to an “In line” or single-cylinder pump. The plunger, which is driven by the camshaft, moves up and down in the body. Fuel, under pressure, moves freely from engine fuel manifold, through the injector, and back into the manifold. At a certain point during the down-stroke, current is applied to the actuator. This current generates a magnetic field within the actuator and causes a high pressure valve to close.

Once this valve is closed, fuel cannot exit the injector back into the engine fuel manifold. The action of the plunger upon the fuel creates very high pressure. This pressure quickly overcomes the mechanical (spring) force holding the nozzle needle on its seat