No. 1 in sealing technology

No. 1 in sealing technology

Freudenberg Sealing Technologies is the world’s leading market and technology specialist.

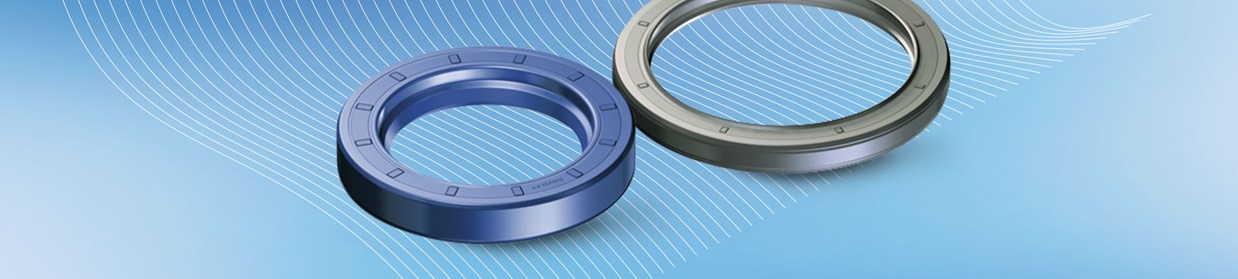

Freudenberg Sealing Technologies is a supplier, development and service partner for customers in different market segments, such as the automotive industry, civil aviation, mechanical engineering, shipbuilding, the food and pharmaceuticals, and agricultural and construction machinery. Freudenberg Sealing Technologies Simmering 500×500 Based on the Simmerring® which was developed by Freudenberg in 1929, Freudenberg Sealing Technologies has built up a broad and continuously expanding range of seals and vibration control technology products – from customized solutions to complete sealing packages. Together with its partners NOK Corporation, Japan, Sigma Freudenberg NOK, India and NOK-Freudenberg Group China, Freudenberg Sealing Technologies has formed a global network with the aim of offering products of the same high quality. The NOK-Freudenberg Group China is a 50:50 Joint Venture between the Japanese NOK Corporate and Freudenberg. In addition, Schwab Vibration Control, Dichtomatik and Corteco fall under the Freudenberg Sealing Technologies umbrella. Schwab Vibration Control is a leading supplier of technology for vibration control components, wind energy solutions, agricultural and construction machinery and other industries. Dichtomatik is Freudenberg’s sales organization in the market for technical seals. Corteco is the Freudenberg Group specialist for the Independent Automotive Aftermarket specializing in spare parts for seals and vibration control as well as service parts such as cabin air filters. As Freudenberg’s largest Business Group, Freudenberg Sealing Technologies generated sales of more than € 2 billion in 2014 and employed some 15,000 people. The company belongs to the Freudenberg Group which, with its Business Areas Seals and Vibration Control Technology, Nonwovens and Filtration, Household Products as well as Specialities and Others, generated sales of more than € 7 billion in 2014 (The 50:50 joint ventures are consolidated on a pro-rata basis) and employed approximately 40,000 associates in around 60 countries.

Freudenberg Sealing Technologies Simmering 500×500 Based on the Simmerring® which was developed by Freudenberg in 1929, Freudenberg Sealing Technologies has built up a broad and continuously expanding range of seals and vibration control technology products – from customized solutions to complete sealing packages. Together with its partners NOK Corporation, Japan, Sigma Freudenberg NOK, India and NOK-Freudenberg Group China, Freudenberg Sealing Technologies has formed a global network with the aim of offering products of the same high quality. The NOK-Freudenberg Group China is a 50:50 Joint Venture between the Japanese NOK Corporate and Freudenberg. In addition, Schwab Vibration Control, Dichtomatik and Corteco fall under the Freudenberg Sealing Technologies umbrella. Schwab Vibration Control is a leading supplier of technology for vibration control components, wind energy solutions, agricultural and construction machinery and other industries. Dichtomatik is Freudenberg’s sales organization in the market for technical seals. Corteco is the Freudenberg Group specialist for the Independent Automotive Aftermarket specializing in spare parts for seals and vibration control as well as service parts such as cabin air filters. As Freudenberg’s largest Business Group, Freudenberg Sealing Technologies generated sales of more than € 2 billion in 2014 and employed some 15,000 people. The company belongs to the Freudenberg Group which, with its Business Areas Seals and Vibration Control Technology, Nonwovens and Filtration, Household Products as well as Specialities and Others, generated sales of more than € 7 billion in 2014 (The 50:50 joint ventures are consolidated on a pro-rata basis) and employed approximately 40,000 associates in around 60 countries.

Sealing and bearing systems are required to perform in a wide range of applications and provide long service life within the mobile hydraulics sector. Trelleborg Sealing Solutions is one of the world market leaders in sealing and bearing systems and also in the development and selection of suitable high-performance materials. From concept, through project development, testing and roll-out, our technicians are available to offer their expertise and experience. The above-average success of our customer-projects is attributed to our customer-focus and partnership approach to attaining appropriate sealing and bearing solutions.

Sealing and bearing systems are required to perform in a wide range of applications and provide long service life within the mobile hydraulics sector. Trelleborg Sealing Solutions is one of the world market leaders in sealing and bearing systems and also in the development and selection of suitable high-performance materials. From concept, through project development, testing and roll-out, our technicians are available to offer their expertise and experience. The above-average success of our customer-projects is attributed to our customer-focus and partnership approach to attaining appropriate sealing and bearing solutions.

| See trelleborg electronic catalog. | See Materials |

Materials list

| ACM | Acrylic Rubber (ACM) shows excellent resistance to ozone, weathering and hot air, although it shows only a medium physical strength, low elasticity and a relatively limited low temperature capability. The operating temperatures range from -20°C and +150°C / -4°F and +302°F (for a short period of time up to +175°C / +347°F). Special types can be used down to -35°C / -31°F. ACM-materials are mainly used in automotive applications which require special resistance to lubricants containing many additives (including sulfur) at high temperatures |

| AU | Zurcon® polyurethane materials have a very good low temperature flexibility, high extrusion resistance and an extremely good abrasion resistance. They have a good hydrolysis resistance, low compression set, high tensile and tear strength and a good resistance to synthetic ester fluids and mineral oils. Zurcon® materials show a very low gas permeability, excellent dynamic sealing properties, no embrittlement in contact with O2 or O3 and are resistant to weathering and aging. The temperature range is between -50°C and +110°C / -58°F and +230°F. |

| CR | In general, the Chloroprene(CR) materials show relatively good resistance to ozone, weathering, chemicals and aging. Also, they show good non-flammability, good mechanical properties and cold flexibility. The operating temperatures range between -40°C and +100°C / -40°F and +446°F (for a short period of time up to +120°C / +248°F). Special types can be used down to -55°C / -67°F. CR materials are found in sealing applications such as refrigerants, for outdoor applications and in the glue industry. |

| EPDM | Ethylene Propylene Diene Monomer (EPDM) shows good heat, ozone and aging resistance. In addition, they also exhibit high levels of elasticity, good low temperature behavior as well as good insulating properties. The operating temperatures of applications for EPDM range between -45°C and +150°C/ -49°F and +302°F (for a short period of time up to +175°C/ +347°F). With sulphur cured types the range is reduced to -45°C and +120°C/ -49°F and +248°F (for short period of time up to +150°C/ +302°F). EPDM can often be found in applications with brake fluids (based on glycol) and hot water. |

| FKM | Depending on structure and fluorine content, Fluoroelastomer (FKM) materials can differ with regards to their chemical resistance and cold-flexibility. FKM is known especially for its non-flammability, low gas permeability and excellent resistance to ozone, weathering and aging. The operating temperatures of the FKM range between -20°C and +200°C/ -4°F and +392°F (for a short period of time up to +230°C / +446°F). Suitably formulated FKM can be used down to -35°C / -31°F. FKM is also often used with mineral based oils and greases at high temperatures. |

| FFKM (Isolast®) | Perfluoroelastomers show broad chemical resistance similar to PTFE as well as good heat resistance. They show low swelling with almost all media. Depending on the material the operating temperatures range between -25°C and +240°C (77°F bis 464°F). Special types can be used up to +325°C (617°F). Applications for FFKM can be mostly found in the chemical and process industries and in all applications with either aggressive environments or high temperatures. |

| FVMQ | Fluorosilicone (FVMQ) has a good heat resistance, very good low temperature flexibility, good electrical properties and excellent resistance to weather, ozone and UV rays. FVMQ shows a significantly better chemical resistance than standard Silicone especially in hydrocarbons, aromatic mineral oils, fuel and low molecular aromatic hydrocarbons e.g. Benzene and Toluene. The temperature range is between -55°C and +175°C / -67°F and +347°F. (temporary up to +200°C / +392°F). |

| HNBR | Hydrogenated Nitrile Butadiene Rubber (HNBR) is made via selective hydrogenation of the Nitrile Rubber (NBR) butadiene groups. The properties of the HNBR rubber depends on the Acrylonitrile (ACN) content whichcontent, which ranges between 18% and 50% as well as on the degree of saturation. HNBR shows good mechanical properties. The operating temperature of HNBR ranges between -30°C and +140°C / -22°F and +284°F (for a short period of time up to +160°C) in contact with mineral oils and greases. Special types can be used down to -40°C / -40°F. |

| IIR | Butyl Rubber shows a very low gas and moisture permeability. In addition IIR also exhibit a good resistance to a great number of organic and inorganic chemicals, ozone, weathering and aging. The electrical insulating properties of IIR are excellent. The temperature range is between -40°C (-40°F) and +110°C (+230°F), for a short period of time +120°C (+248°F). |

| NBR | The properties of the Nitrile Rubber (NBR) depend mainly on the Acrylonitrile (ACN) content whichcontent, which ranges between 18% and 50%. In generalgeneral, they show good mechanical properties. The operating temperatures range between -30°C and +100°C / -22°F and +212°F (for a short period of time up to +120°C / +248°F). Suitable Suitably formulated NBR can be used down to -60°C / -76°F. NBR is mostly used with mineral based oils and greases. |

| VMQ | Silicon Rubber (VMQ) has a very good heat resistance, very good low temperature flexibility, good electrical properties and excellent resistance to weather, ozone and UV rays. Specific VMQ formulations are resistant to aliphatic engine and gear box oils, water up to +100°C / +212°F and high molecular chlorinated hydrocarbons (e.g. Chlophen). The temperature range is between -60°C and +200°C / -76°F and +392°F. (temporary up to +230°C/ +446°F). |